SOLUTION

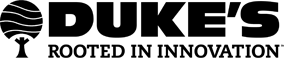

To address these challenges, a comprehensive investigation and condition assessment were conducted for the Lynnwood and Black Branch sub-basins. A “system triage” approach was use d, incorporating multiple technologies:

SL-RAT Acoustic Pipe Inspection: 238,214 linear feet of sewer pipe were acoustically inspected to evaluate blockages and obstructions.

Micro Detection Sensors: 238,214 linear feet of sewer pipe were monitored using 187 level-based sensors deployed every 1,200 feet to detect inflow and infiltration sources.

Manhole Inspection: 1,168 manholes received a NASSCO Level 2 inspection to assess structural condition and I&I contributions.

Area Velocity Flow Monitoring: Monitored key areas within the Micro Detection Area.

IMPLEMENTATION

The investigation revealed specific areas requiring immediate attention:

Pipe Condition: 16,000 linear feet (7%) of inspected pipe received a BLOCKED or POOR rating based on SL-RAT technology.

Manhole Condition: 115 of the 1,168 inspected manholes (12%) were ranked as severe, indicating significant rehabilitation needs.

Inflow and Infiltration Contributions: 51,200 linear feet (24%) of inspected pipe were identified as contributing significantly to I&I.

Recommendations implemented included:

CCTV Inspection: Targeted inspection of segments with BLOCKED or POOR SL-RAT scores.

Manhole Rehabilitation: Rehabilitated 306 manholes, including 115 severe-ranked manholes and 191 additional manholes identified through broader inspection.

Smoke Testing: Conducted smoke testing on 85,147 linear feet of pipe to further identify inflow sources.