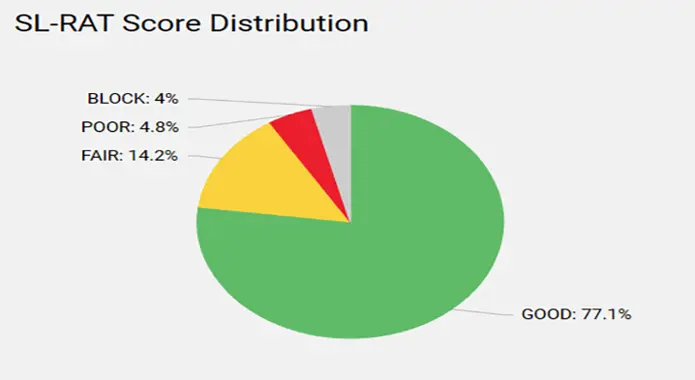

Duke’s uses a pipeline assessment tool leveraging acoustic technology to identify blockage and capacity issues in gravity sewers within minutes at a fraction of the cost of traditional methods. This quick tool allows for up to 10,000 ft per day of cost-effective system evaluation. The transmitter (TX) sits on top of adjacent manholes, transmitting a sound wave through the sewer line to the receiver (RX). Additionally, each component is equipped with GPS and the ability to communicate between the TX and RX via RF – thus providing your organization with world class data labeling, data registration, and test validation capabilities.

Duke's Insight 360

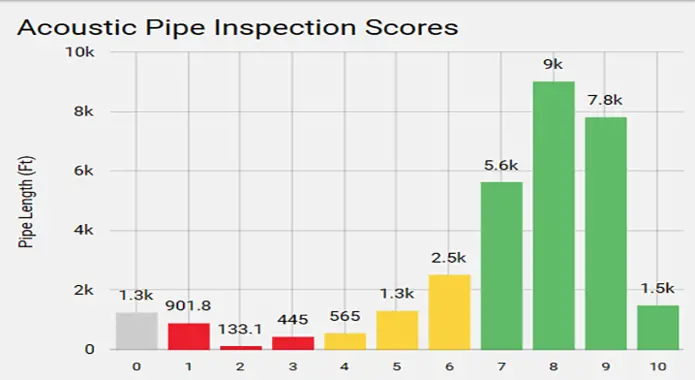

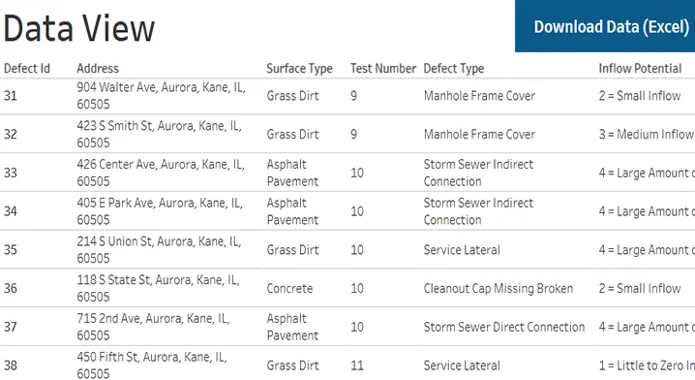

Duke’s Insight 360 is an intuitive online platform for summarizing and analyzing the inspection data. With the click of a button, users can easily access:

- Interactive Map

- Interactive Results Table

- Printable GIS based Maps

- Summary Report (PDF format)

Users can quickly identify problem areas and view data from anywhere with an internet connection, providing maps, tables, reports upon project completion for efficient management of sewer collection systems.